|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Company Profile  |

Road System Technologies (India) Pvt. Ltd was incorporation with its principal activity being the manufacture of Thermoplastic Road Marking material. Backed up by proven Malaysian Technology in the manufacturing process, we are dedicated for improving Road & Highways safety in India. The factory is located at Chennai in the State of Tamilnadu, India with easy access to rail, road, sea and air transportation systems.

We have been established with Malaysian Technology, with Directors and Shareholders having more than 10 years of experience in the similar business in Malaysia.

| ||||||||||

Production Capabilities |

Our Production facilities are capable to produce 900 MT per month and enable us to meet various demands domestically in time and even for any export enquires.

The production is managed by a total quality-manufacturing program to assure product specifications are met.

| ||||||||||

Laboratory & Quality |

We have with us an established laboratory to undertake various kinds of tests needed for thermoplastic road marking material, which enables us to implement continuous quality control and quality checks to assure quality product to customers.

| ||||||||||

Product Profile  |

We mainly produce two standards in two colors of Thermoplastic road marking materials

MOST White Branded as RST MOST White Powder MOST White Branded as RST MOST Yellow Powder MOST White Branded as RST Super White Powder MOST White Branded as RST Super Yellow Powder

| ||||||||||

Raw Materials |

All the raw material which are necessary for Thermoplastic road marking has been utilized and more over all this raw materials have been imported from prime manufacturers of respective materials.

All the raw materials which goes into production are selected and tested first in our in-house laboratory and then only it goes for production. More over we keep track of every batch of raw material used in production, Ensuring constant quality control and quality checks.

| ||||||||||

Finished Product |

After production, the finished product is properly weighed and packed in good condition and labeled accordingly. RST Super White and Super Yellow are packed in 25 kg bags for easy handling, storage and transportation.

| ||||||||||

Testing of product |

We test our finished product batch wise to ensure that our quality control program does not miss at any instance by which we assure our customer a quality product.

| ||||||||||

Application |

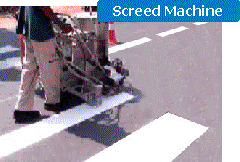

Methods of application is by screed machine, extrusion and spray. Generally, good application technique would inculcate the following minimum pre-requisites.

1. Cleaning and preparation of pavement or substrate

2. Application of primer where required

3. Melting of thermoplastic to specified temperature

4. Application at the specified thickness, width and length

5. Immediate application of glass beads at specified rate

RST Super White and RST Super Yellow will enable you to provide excellent guidance to road users as well as providing excellent weatherability, durability and visibility. They also provide excellent cost effectiveness.

|