|

|

|

|

|

|

|

|

| APPLICATION |

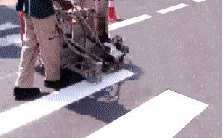

Methods of application is by screed machine, extrusion and spray. Generally, good application technique would inculcate the following minimum pre-requisites.

1. Cleaning and preparation of pavement or substrate 2. Application of primer where required 3. Melting of thermoplastic to specified temperature 4. Application at the specified thickness, width and length 5. Immediate application of glass beads at specified rate RST Super White and RST Super Yellow will enable you to provide excellent guidance to road users as well as providing excellent weatherability, durability and visibility. They also provide excellent cost effectiveness. |

| SURFACE PREPARATION |

1.Asphalt surface preparation must be dry, free from dust, dirt, grease and loose materials.

2.Concrete surfaces must be dry, clean and free from laitance and dust. 3.Concrete surfaces previously treated with curing compound must be treated with a concrete prime sealer before application. |

| METHOD OF APPLICATION |

RST materials can be applied by screed, extrusion, and spray application at 180 C - 200 C. Special markings can be applied manually.

1.Set temperature of the pre-heater so that material temperature is between 180 C - 210 C should be fitted with stirrer to ensure smooth consistency viscosity and uniform heating. 2.When Pre-heater is full, mix for a few minutes at 180 C - 210C 3.Offload the hot material to the application machine pre-heated tank while mixing at 180 C - 210 C 4.Reference line for machine shall then be marked with nylon ropes and chalk. 5.The material shall be screeded / extruded at a standard thickness of 2.5mm and the finished line shall be ensured to the extent reasonably possible to be free from ruggedness on sides and ends and true in plane with the general alignment of the carriageway. 6.Apply glass beads simultaneously over the fresh hot marking for initial reflectivity. Glass beads should be dispensed evenly through a dispenser. A surface application rate of 250 - 350 gms/sqm is recommended for maximum reflectivity and durability. 7.When the application cannot be done using the machine, approved manual methods shall be used. Always wear protective gloves and clothing when handling heated material. |

|

|

|

|

|

|

|

|

| Surface Cleaning | Line Marking | Pre Heating | Filling Applicator | Trafic Control | Paint Laying | Beads Dispencing | Marked Road |

| BEADS FOR EVERY REFLECTIVE NEED |

Road marking visibility at night can only be achieved by the application of tiny glass beads onto the surface and incorporated within road marking materials. These beads (Safety Marking Spheres) are manufactured in a full range of sizes and offer long life and durability to thermoplastic road markings |

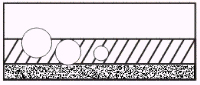

| BEAD GRADATION |

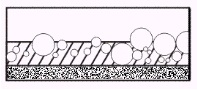

Glass beads are graded in precise size ranges to optimize reflective performance throughout the life of the line. As markings wear under traffic flow, some spheres are dislodged allowing previously covered spheres to become exposed and act as reflective elements. |

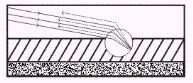

| DEGREE OF EMBEDMENT |

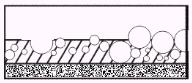

Maximum reflectivity of individual glass spheres occurs when the optimum degree of embedment is achieved. This occurs when 60% of the bead is below the surface of the pavement marking material and 40% is above. |

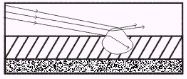

| ROUNDNESS |

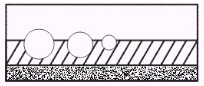

Optimum retro - reflection requires true round spheres. Non round spheres do not reflect light efficiently but scatter it in random directions. Strict quality control is necessary to ensure correct amounts of true round spheres. |

| Bead Gradation | Degree Of Embedment | Roundness | |||

|

|

|

|

|

|

| Newly Painted Line | Line After Wear | Proper Embedment | Improper Embedment | Light Returned By True Round Sphere |

Light Scattered By Non Round Sphere |